Retrofit Vs Newbuild: What is the climate-conscious strategy?

In this success storyOverviewFindingsConclusionShare

-

Share

-

The Dolphin 57 vessel was chosen due to its widespread presence and critical juncture in its operational lifespan. With most of the 450+ Dolphin 57 vessels worldwide approaching their half-life, we at Azolla wanted to crack this LCA and help owners make intelligent, informed decisions about profitability and environmental responsibility.

Overview

The task at hand is to determine whether retrofitting a existing class of bulker (Dolphin 57) and operating till it's end-of-life, is more energy efficient than ordering a new ship of similar dimension.

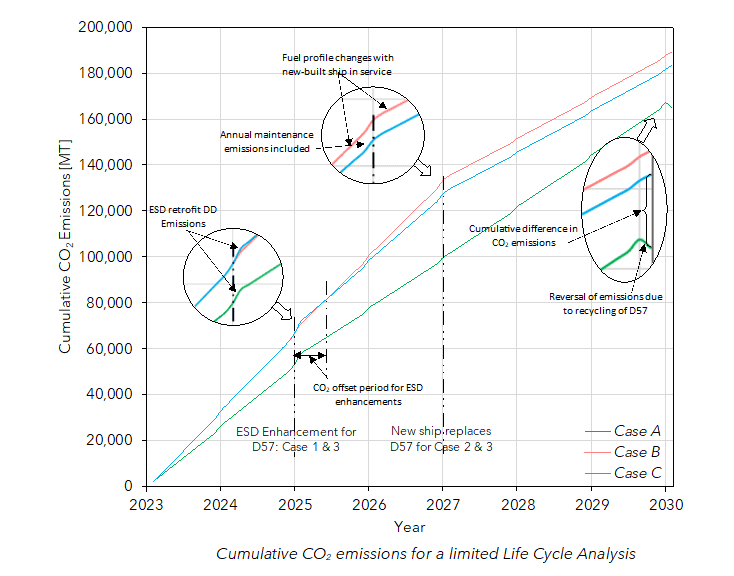

To find the answer to this, we quantified the limited LCA of CO2 emission of both these ships, which starts from the current year and ends when the existing bulker reaches its end-of-life and is scrapped.

Findings

On analysis, we found that his situation gave rise to 3 distinctive pathways in which the Shipowner can carry out the operations. These pathways are presented as follows:

- Case A: Existing D57 (2009 built) is acquired and operated, and its efficiency is enhanced in the next dry-dock (assumed currently in ultimo-2024), customarily operated after that, and scrapped by the year 2030.

- Case B: A newly built Supramax vessel is ordered on the current date, delivered around 2027, and operated until 2030. From the present date till the delivery of the new vessel (2027), an existing vessel without ESD enhancement is operated.

- Case C: A built Supramax vessel is ordered on the current date with its delivery around 2027 and operated after that till 2030. From the present date till delivery of the new vessel (2027), an existing vessel is operated where ESD enhancements are made in its next possible DD upcoming dry-dock (assumed currently in ultimo-2024).

Having set up the premises, we identified vital contributors to accurately assess CO2 emissions at every significant stage of a vessel's lifecycle. That encompassed:

- Product Stage: Evaluating emissions associated with raw materials, supply chain, manufacturing, equipment, and construction/assembly.

- Use Stage: Meticulously examining emissions linked to raw materials, manufacturing, equipment, fuel consumption, maintenance, auxiliary activities, and enhancements.

- End of Life: Conducting a comprehensive assessment of emissions related to deconstruction, waste processing, disposal, transportation, and the potential for reuse, recycling, or recovery of materials.

Conclusion

Our investigation infers that enhancing an existing bulker with energy-efficient devices, scrapping it at its end-of-life, and recycling as many parts as possible cause the most negligible environmental impact.

Retrofitting the existing vessel in our case:

-Produces 12.5% lower CO2 emissions compared to ordering a new vessel

-Offsets CO2 emissions faster than the newbuild

-Offsets payback time much sooner compared to newbuild

The primary reason is the need for business continuity with additional new shipbuilding emissions. Furthermore, it can be concluded that the environmental impact can be lowered by preponing an ESD enhancement docking.

Share

-

Evaluate your vessel's LCA to understand its viability.profitability.efficiency.viability.