How did Arcelor Mittal track efficiency post propeller retrofit using Azolla’s performance monitoring solutions?

In this success storyThe PremiseProblemSolutionConclusionValidationAzolla thanks ArcellorMittalShare

-

Share

-

I'm delighted to express my utmost satisfaction with consultation and project management services provided by Azolla. Their expertise in EAS solution and implementation, BWTS installation, EEXI and EPL installations for our entire fleet has been truly remarkable. I whole heartedly recommend Azolla for its exceptional services and professionalism.

The Premise

In the quest for sustainability, ArcelorMittal, a global steel manufacturing leader, set an ambitious mission - to achieve net-zero emissions by the year 2050. As one of the world's foremost steel producers, the company's pledge to attain net-zero emissions carries significant weight, serving as a beacon for industries worldwide to follow suit in mitigating climate change.

As a part of this journey, they retrofitted an optimized propeller to one of their vessels, Vessel -A (name changed/Place holder name), with a singular objective: to enhance vessel efficiency and drastically reduce its carbon footprint.

Problem

Seeking to validate the gains, ArcelorMittal turned to Azolla. Our task was straightforward: meticulously monitor and evaluate the actual performance improvements on Vessel-A (Which was recently retrofitted with an optimized propeller).

Solution

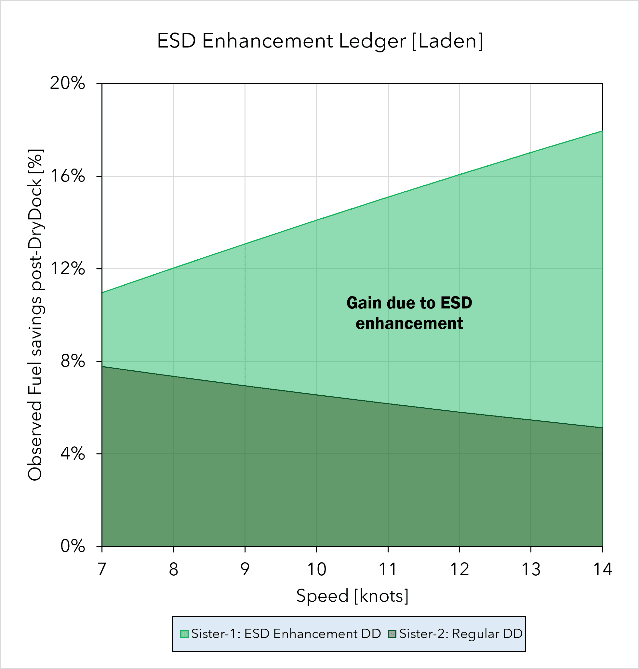

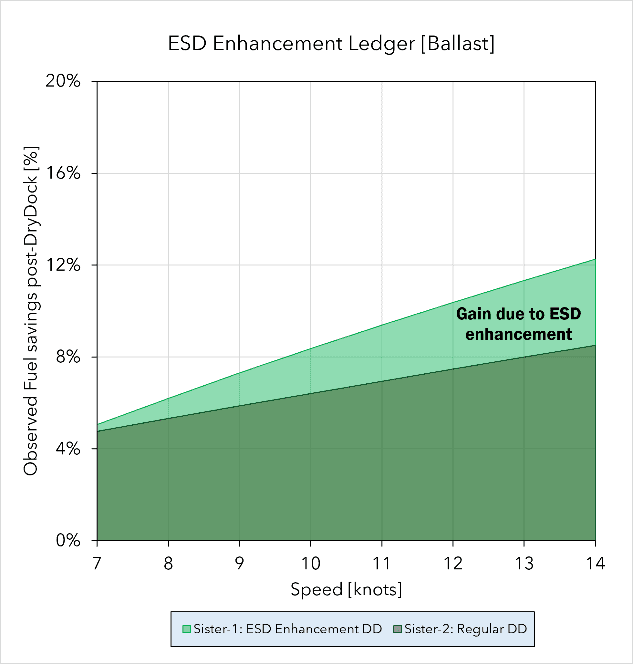

Interestingly, Vessel B (name changed/Place holder name) and Vessel A's sister vessel shared similar dry-dock dates and operational profiles. The only noticeable difference lay in the propulsion system - while Vessel-A boasted the optimized propeller, Vessel-B remained unmodified. This parallel between the two sister vessels presented a unique opportunity for ArcelorMittal to understand the gains achieved through the retrofit and benchmark these gains against the vessel's unaltered counterpart.

Conclusion

Our analysis of the Noon report data unveiled concrete evidence of emission reductions achieved through the propeller retrofit. The figures spoke volumes - a 7% reduction in emissions at charter party Laden speed and a 4% reduction at charter party Ballast speed.

But this must be validated.

Validation

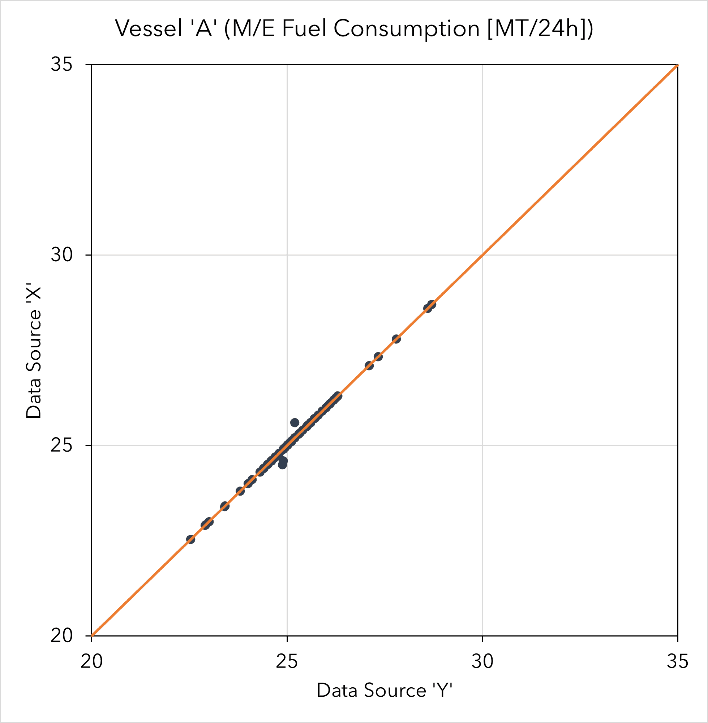

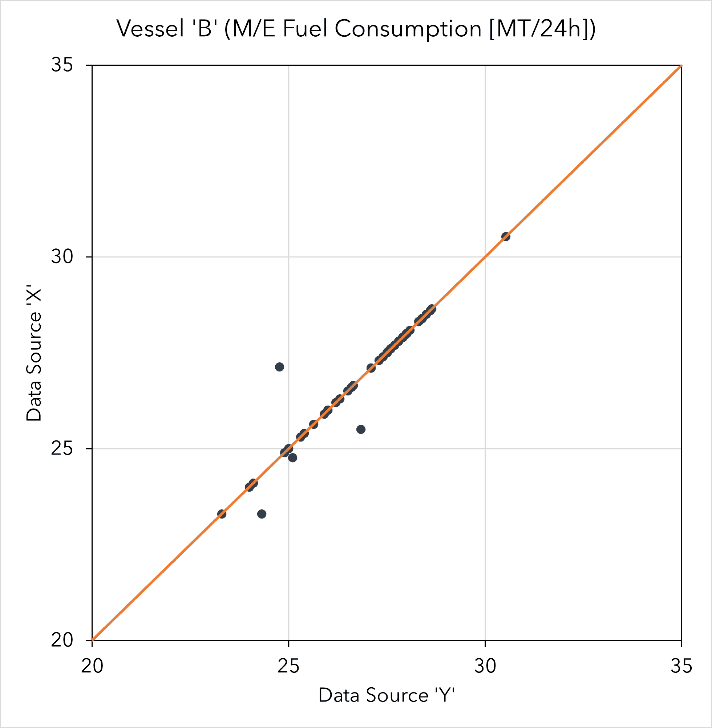

With dual data streams available (manual and auto-logger data), the conclusion was further validated by comparing and mapping the data sent by the On-board auto-logger, providing confidence in our findings.

Azolla thanks ArcellorMittal

In the dynamic landscape of maritime decarbonization, tracking and analyzing performance metrics are crucial to ensuring that investments yield the desired outcomes.

Azolla acknowledges the profound significance of ArcelorMittal's initiative to retrofit an optimized propeller and monitor the performance gain results. We thank them for having Azolla as their decarbonization partner in their pursuit of net zero.

Our partnership will continue to flourish as we work together to navigate the complexities of maritime operations and drive efficiency and sustainability across their entire fleet.

Share

-

Understand how Azolla can help you Monitor Performance.Decarbonize.Unlock your vessel.Monitor Performance.